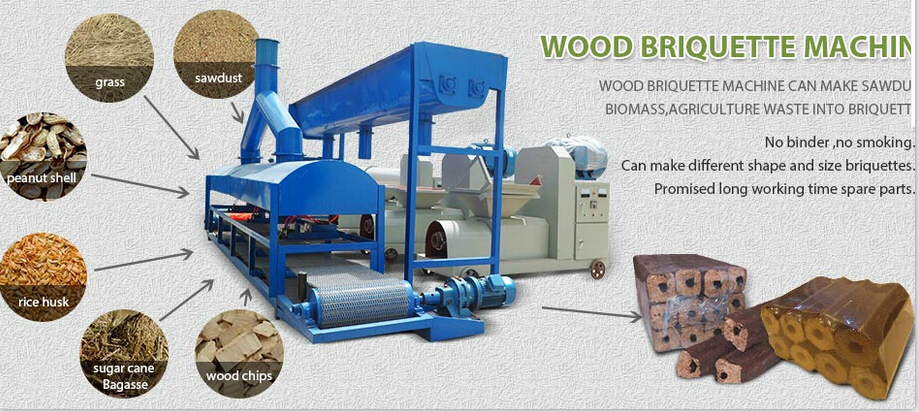

Biomass Charcoal Briquette Machine is mainly used to corn stalk, soybean, cotton, wheat, rice husk, peanut shells, sawdust, weeds, twigs and other materials. After carbonization, the whole process does not produce pollution, biomass carbon formation, is the special molding equipment.

Biomass Charcoal Briquette Machine is mainly used to corn stalk, soybean, cotton, wheat, rice husk, peanut shells, sawdust, weeds, twigs and other materials. After carbonization, the whole process does not produce pollution, biomass carbon formation, is the special molding equipment.

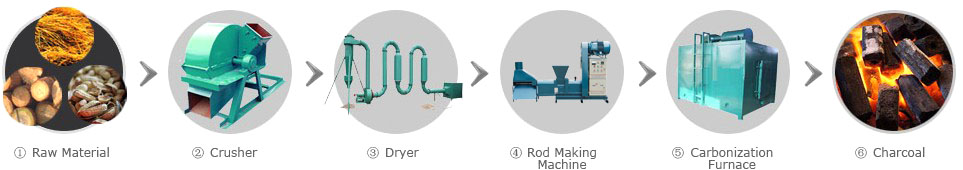

Flowchart of Biomass Charcoal Briquette Machine

Advantage of Biomass Charcoal Briquette Machine

(1) Energy conservation and environmental protection,no waste gas,clean and health.

(2) Inflammable,high calorific value, 4000-6000 calories.

Strcure of Biomass Charcoal Briquette Machine

Body: Consist of platen, engine base, forming the skeleton entity.

Driving parts: Consists of motor, belt pulley, gear, transmission shaft, etc. The motor make the gear shaft rotating through belt pulley, and through two gears pass to axis, and then by a pair of bevel gear and the axis of rotation to drive the dial, and then pass to the four panel movement.

Feeding part: Is composed of spindle, hopper, mixer, through the rotation of the spindle, automatic feeding and stir.

Punching parts: Intermittent work, feeding, stamping, molding

Transmission parts: By the transmission rack, pulley, and other components of the conveyor belt, conveyor frame can be adjusted by the adjusting screw on the elastic.

Biomass Charcoal Briquette Machine details show

In order to meet the different needs of different customers,our factory has designed different types of mold and all of the molds are produced by ourselves according to the customer's requirements,meanwhile the mold materials are use durable.

The Mold

Don't just see the finished product looks good, the most important is main materials used in the equipment parts such as models,bearing,size,weight and so on.Choose what material is the key to affect the service life of the biomass charcoal briquette machine.

Shape: shape can be round, cylindrical, square, rectangle, polygonal, hexagonal, etc. Or you can have your own ideal shape.

Size: the final size is according to the shape and the machine mould, also you can decide it under certain range.

Characteristics: the product is processed into high density, combustion time is long, non-toxic, smoke-free, etc.

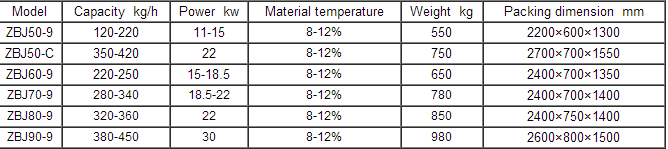

Technical Parameter of Biomass Charcoal Briquette Machine

Inquiry* Describe Your Buying Requirements in Detail,We will reply you in 24 hours!