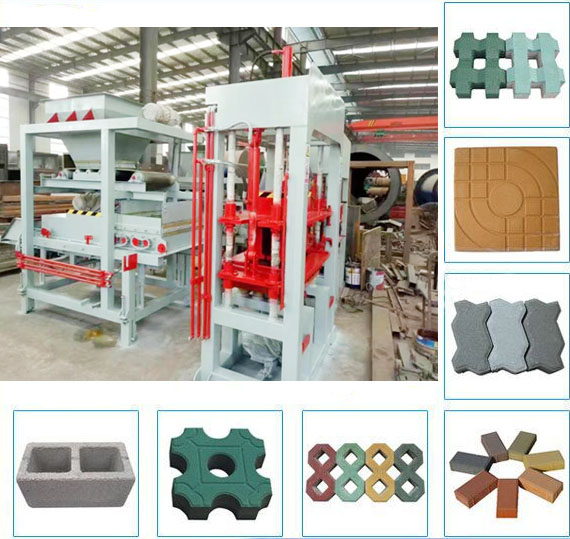

Brick Making machine, this machine can make except normal hollow bricks,standard bricks, also can make building cushion blocks,paver color bricks,bread bricks.

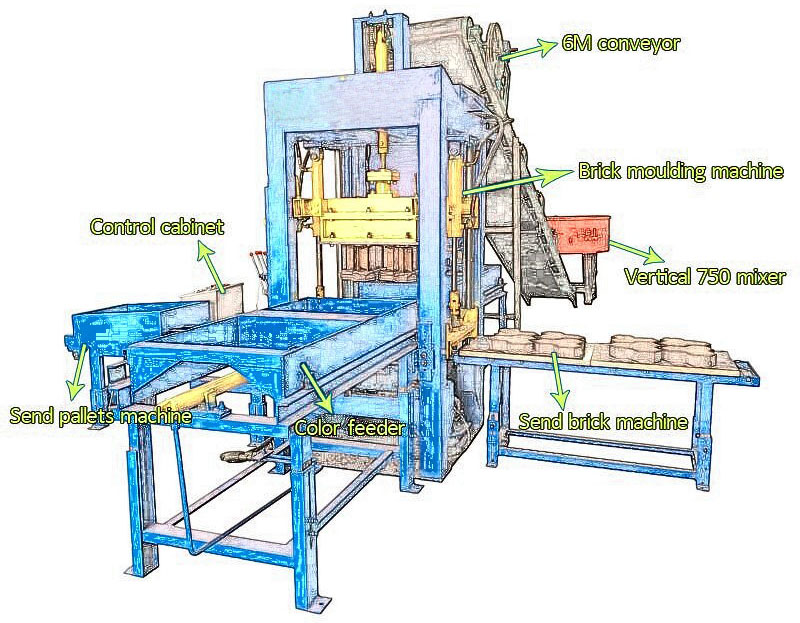

Brick Making machine, this machine can make except normal hollow bricks,standard bricks, also can make building cushion blocks,paver color bricks,bread bricks, Whole set of brick making machine used full hydraulic pressure system, can reach press and vibrating combined, high density of finished bricks,different type bricks, smooth surface, difficult be out of shape, easy to demould, low failure rate, the best choice to produce non burning blocks, and also design seconary color feeding device, can avoid to make the bricks that need color feeding manully, renew the color feeding system, greatly decrease the investment of customer,thus the brick mould uses wire-cutting to meet various demand, help our customer make profit.

By material:cement brick machine/concrete brick machine/fly ash brick machine/slag brick making machine

By shape or pattern:interlocking brick machine/hollow brick machine/solid brick machine/paver block machine

By operation:hydraulic press Automatic brick machine,Semi-automatic brick making machine, Manul brick making machine.

Brick making machine in market are different type and multifunctional choice. But the quality good and bad are intermingled.Please make it clear it is Lanyu Brand and following points

Environmental raw material:Concrete,cement,fly ash and slag are nomarl material everywhere for brick making machine,easy to use;

Scientific Working process:Hydraulic pressure adding vibration system in brick making machine,make the finished bricks more stable quality;

Germany block machine advanced technology, low noise, weight exceeds the weight of domestic productionmodels 30%, shock-absorbing effect; Hydraulic control system consists of a large-volume oil tank automatic pressure systems in brick making machine,high and low voltage control systems, simultaneous removal of the membrane device.Equipped with cooling and heating system on brick making machine, can ensure the oil temperature and viscosity of the entire hydraulic system is more stable, reliable and advanced oil filtration system, can guarantee the stability of the service life of hydraulic components and hydraulic systems.Rotate fast-distributing mode, ensures the bearing block, fly ash lightweight aggregate blocks, blocks full of dense,uniform cloth, cloth rapidly implement vibrating fabric, shorter cycle time, improve production efficiency and uniquesingle-mode resonance system.The exciting focus on mould,both guaranteed block compactness and reduced chassis vibration and noise. Using super strong steel and special welding technology, good rigidity, vibration-proof, long service life. Four-bar guidance mode and Super staying power pilot bearing to ensure accurate movement of punch and die.Moving parts about brick making machine are made of bearing coupling for easy lubrication and less loss.

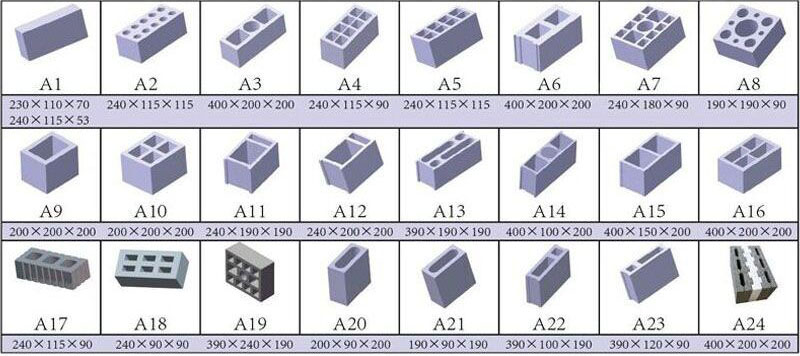

Finished Products specification of new Brick Machine

The main technical parameters of Brick Machine

| Molding cycle | 15-20 s/mould | Product specification |

| Vibration frequency | 1000-4200 times/min (can adjust) |

240*115*53 mm (solid brick 48 pcs/mould) |

| Vibration force | 20-50 KN(can adjust) |

390*190*190 mm (hollow brick 10 pcs/mould ) |

| Total power | 41(kw) |

240*115*90 mm (mutihole brick 24 pcs/ mould ) |

| Theory daily production | 115,200 pcs/day (solid brick ) |

250*250*60 mm (paving brick 6 pcs/ mould ) |

| Pallet dimension | 1080*860*35-40mm (bamboo making ) |

225*111*60 mm (paving brick 24 pcs/ mould ) |

| Machine weight | 14.6 T |

200*100*60 mm (paving brick 24 pcs/ mould ) |

| Overall dimension | 3500*2100*2600mm |

Inquiry* Describe Your Buying Requirements in Detail,We will reply you in 24 hours!