Coal Briquete Machine or coal briquetting machine is also called coal ash briquette machines, coal briquetting plant or coal briquette plant whose molding process can be classified into cold briquetting and hot briquetting, and the former occupies an important position.

Coal Briquete Machine or coal briquetting machine is also called coal ash briquette machines, coal briquetting plant or coal briquette plant whose molding process can be classified into cold briquetting and hot briquetting, and the former occupies an important position.

The coal briquette press machine is mainly used to press powder materials that are hard to be shaped. The coal briquetting machine has the features of strong pressing pressure, adjustable revolution and screw conveying device. This coal briquette machine can save energy and protect the environment and the final products are convenient to be transported, thus improving the utilization of the waste materials and have excellent economic and social benefits. In addition, the power consumption of this coal briquetting machine is low.

The development of our coal briquetting plant started relatively late, while the developed countries of west Europe have screened the coals once they get to the ground, making the pulverized coal into ball. As a result, we cannot see any pulverized coal in the process of circulation at all.

According to the development of China's economy and environment protection, cleaning coal technology must be vigorously developed in our country. Features of coal briquetting plant or coal briquette machine include energy conservation, pollution abatement and high economic benefits with small investments, which makes the good foundation and development direction for its wide promotion.

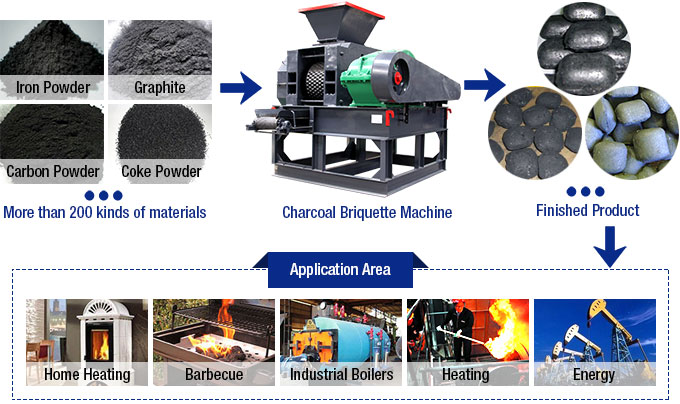

Structural Features of Coal Briquetting Machine

The performance of coal briquetting machine is mainly determined by the roller skin of main engine. This type of coal briquette machine is casted with 65 manganese, and with special heat treatment, its hardness can reach over 58°„. The roller skin adopts composite assembly so that it can be changed when abraded. This briquette machine has a shock absorber which can better protect the equipment from the impact of hard materials. The briquette machine is designed with ball bowl adjustable device to make sure the ball bowls of the two rollers are always in the adjustable range.

Application of Coal Briquetting Machine

Coal Briquetting Machine can be used in refractory, power plant, metallurgy, energy sector, chemistry, heating and other industries using boiler for steam generation. It can press powdery materials like coal powder, iron powder, aluminum powder, chromium powder, oxide scale, carbon powder, lime powder, fluorite powder, etc.

Technical Data of Coal Briquetting Machine

| Performance | HL-360 | HL-400 | HL-500 | HL-650 | |

| Output | hour (t/h) | 4 | 8 | 11 | 18 |

| Annual output (million t/y) | 1 | 2 | 3 | 5 | |

| Roller breadth (mm) | 250 | 280 | 300 | 336 | |

| Roller diameter (mm) | 360 | 400 | 500 | 650 | |

| Power(kw) | 7.5 | 11-15 | 18.5-22 | 20-30 | |

| Speed of mainshaft (r/min) | 18 | 15 | 13 | 13 | |

| Reducer | ZQ350 | ZQ400 | ZQ500 | ZQ650 | |

| ZQ400 | ZQ500 | ZQ650 | ZQ750 | ||

| Pressure form | Oblique iron constant pressure | Oblique iron constant pressure | Oblique iron constant pressure | Oblique iron constant pressure | |

| Axle bed pull rod | Axle bed pull rod | Hydraulic type | Hydraulic type | ||

| Interchangeable of hydraulic and constant pressure | Interchangeable of hydraulic and constant pressure | ||||

| Roller texture | 65Mn | 65Mn | 65Mn | 65Mn | |

| 9cr2Mn | 9cr2Mn | ||||

| Alloy steel | Alloy steel | Alloy steel | Alloy steel | ||

| Structural style | Double-roller&single pressure type | Double-roller&single pressure type | Double-roller&single pressure type | Double-roller&single pressure type | |

| Four-roller&dual pressure type | Four-roller&dual pressure type | Four-roller&dual pressure type | Four-roller&dual pressure type | ||

| Mainshaft bearing | 319*4 | 319*4 | 2097724*4 | 2097724*4 | |

| Principal axis | Ø95mm | Ø110mm | Ø135mm | Ø165mm | |

| 45# steel | 45# steel | Forge piece | Forge piece | ||

| Spherical size | User defined | User defined | User defined | User defined | |

| Performance | HL-750 | HL-850 | HL-1250 | Instruction | ||

| Output | hour (t/h) | 25 | 35 | 70 | ||

| Annual output (million t/y) | 7 | 10 | 20 | |||

| Roller breadth (mm) | 400 | 500 | 650 | £®65Mn£© | ||

| Roller diameter (mm) | 750 | 850 | 1250 | |||

| Power(kw) | 45 | 75 | 130 | According to the materials | ||

| Speed of mainshaft (r/min) | 13 | 10 | 10 | |||

| Reducer | ZQ750 | ZQ850 | ZQ1250 | Standard configuration | ||

| Reinforced configuration | ||||||

| Pressure form | Oblique iron constant pressure | Oblique iron constant pressure | Oblique iron constant pressure | Optional | ||

| Hydraulic type | Hydraulic type | Hydraulic type | ||||

| Interchangeable of hydraulic and constant pressure | Interchangeable of hydraulic and constant pressure | Interchangeable of hydraulic and constant pressure | ||||

| Roller texture | 65Mn | 65Mn | 65Mn | Casting | Either type | |

| 9cr2Mn | 9cr2Mn | 9cr2Mn | Forging | |||

| Alloy steel | Alloy steel | Alloy steel |

Pressure casting |

|||

| Structural style | Double-roller&single pressure type | Double-roller&single pressure type | Double-roller&single pressure type | Either type | ||

| Four-roller&dual pressure type | Four-roller&dual pressure type | Four-roller&dual pressure type | ||||

| Mainshaft bearing | 2097724*4 | 2097724*4 | 2097724*4 | |||

| Principal axis | Ø165mm | Ø180mm | Ø225mm | |||

| Forge piece | Forge piece | Forge piece | Hardening and tempering | |||

| Spherical size | User defined | User defined | User defined | Generally choose 30-60mm | ||

Inquiry* Describe Your Buying Requirements in Detail,We will reply you in 24 hours!