Standard Briquette Machine, with other names of briquette machine, briquette press machine and briquette making machine. The briquette making machine or briquette press machine can be used to press various powders, scrap, waste residue such as pulverized coal, iron powder, coking coal, aluminum ash, iron filings, coke breeze and so on.

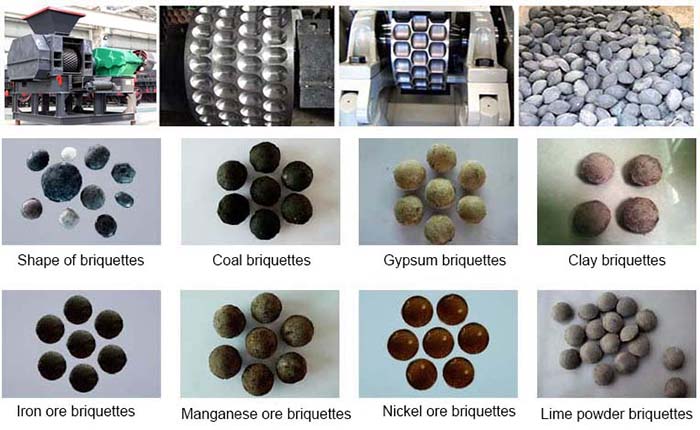

Standard Briquette Machine, with other names of briquette machine, briquette press machine and briquette making machine. The briquette making machine or briquette press machine can be used to press various powders, scrap, waste residue such as pulverized coal, iron powder, coking coal, aluminum ash, iron filings, iron oxide scale, carbon dust, powdered carbon, slag, gypsum, gangue, sludge, kaolin, active carbon, coke breeze and so on. The briquette press machines are widely used in refractory, powder plant, metallurgical, chemical engineering, energy, transportation, heating and other industries. The molding materials that made by the briquette making machine are energy conservation and environment protection and easy to carry. The briquette machine also improves the utilization rate of waste, which has significant economic benefits and social benefits.

Structure Principle of Standard Briquette Machine

The roller sheet of the briquetting machine is cast by manganese, the hardness of which can reach up to 58 degrees after special processing. Because the roller sheet adopts combination assembly, it is adjustable after abrasion. The buffer device in the briquette machine can protect the equipment from being impacted by the hard object to a certain extent.

Working Principle of Standard Briquette Machine

The briquette machine uses main motor to transmit the motive power to speed reducer through the V-shape triangle belt and to main drive spindle through coupling, and then uses the main driven split gear to send it to the main driven spindle to make the two rollers fall into step (inverted running with uniform speed).

The driven roller is held by the piston of the hydraulic oil cylinder, the hydraulic system completes the circuit and the control valve in the hydraulic system keeps the system pressure. Materials are entered evenly into the feeding hopper of briquette machine through the rationing equipment, and then poured into the breaker rolls evenly adjusted by the regulating sluice. The two big rollers push raw materials with high pressure force, to press them into briquettes, and successfully complete drop from rollers.

Technical Parameters of Standard Briquette Machine

| Performance | HL-360 | HL-400 | HL-500 | HL-650 | |

| Output | hour (t/h) | 4 | 8 | 11 | 18 |

| Annual output (million t/y) | 1 | 2 | 3 | 5 | |

| Roller breadth (mm) | 250 | 280 | 300 | 336 | |

| Roller diameter (mm) | 360 | 400 | 500 | 650 | |

| Power(kw) | 7.5 | 11-15 | 18.5-22 | 20-30 | |

| Speed of mainshaft (r/min) | 18 | 15 | 13 | 13 | |

| Reducer | ZQ350 | ZQ400 | ZQ500 | ZQ650 | |

| ZQ400 | ZQ500 | ZQ650 | ZQ750 | ||

| Pressure form | Oblique iron constant pressure | Oblique iron constant pressure | Oblique iron constant pressure | Oblique iron constant pressure | |

| Axle bed pull rod | Axle bed pull rod | Hydraulic type | Hydraulic type | ||

| Interchangeable of hydraulic and constant pressure | Interchangeable of hydraulic and constant pressure | ||||

| Roller texture | 65Mn | 65Mn | 65Mn | 65Mn | |

| 9cr2Mn | 9cr2Mn | ||||

| Alloy steel | Alloy steel | Alloy steel | Alloy steel | ||

| Structural style | Double-roller&single pressure type | Double-roller&single pressure type | Double-roller&single pressure type | Double-roller&single pressure type | |

| Four-roller&dual pressure type | Four-roller&dual pressure type | Four-roller&dual pressure type | Four-roller&dual pressure type | ||

| Mainshaft bearing | 319*4 | 319*4 | 2097724*4 | 2097724*4 | |

| Principal axis | Ø95mm | Ø110mm | Ø135mm | Ø165mm | |

| 45# steel | 45# steel | Forge piece | Forge piece | ||

| Spherical size | User defined | User defined | User defined | User defined | |

| Performance | HL-750 | HL-850 | HL-1250 | Instruction | ||

| Output | hour (t/h) | 25 | 35 | 70 | ||

| Annual output (million t/y) | 7 | 10 | 20 | |||

| Roller breadth (mm) | 400 | 500 | 650 | £®65Mn£© | ||

| Roller diameter (mm) | 750 | 850 | 1250 | |||

| Power(kw) | 45 | 75 | 130 | According to the materials | ||

| Speed of mainshaft (r/min) | 13 | 10 | 10 | |||

| Reducer | ZQ750 | ZQ850 | ZQ1250 | Standard configuration | ||

| Reinforced configuration | ||||||

| Pressure form | Oblique iron constant pressure | Oblique iron constant pressure | Oblique iron constant pressure | Optional | ||

| Hydraulic type | Hydraulic type | Hydraulic type | ||||

| Interchangeable of hydraulic and constant pressure | Interchangeable of hydraulic and constant pressure | Interchangeable of hydraulic and constant pressure | ||||

| Roller texture | 65Mn | 65Mn | 65Mn | Casting | Either type | |

| 9cr2Mn | 9cr2Mn | 9cr2Mn | Forging | |||

| Alloy steel | Alloy steel | Alloy steel |

Pressure casting |

|||

| Structural style | Double-roller&single pressure type | Double-roller&single pressure type | Double-roller&single pressure type | Either type | ||

| Four-roller&dual pressure type | Four-roller&dual pressure type | Four-roller&dual pressure type | ||||

| Mainshaft bearing | 2097724*4 | 2097724*4 | 2097724*4 | |||

| Principal axis | Ø165mm | Ø180mm | Ø225mm | |||

| Forge piece | Forge piece | Forge piece | Hardening and tempering | |||

| Spherical size | User defined | User defined | User defined | Generally choose 30-60mm | ||

Inquiry* Describe Your Buying Requirements in Detail,We will reply you in 24 hours!