Hammer crusher is also called hammer mill crusher. Hammer crusher is a single-stage crushing machine that can directly crush the materials whose maximum granularity is 600-180 mm to 25 mm or below. Zhengzhou Lanyu Mechanical is famous hammer crusher manufacturer or hammer mill crusher supplier in China.

Zhengzhou Lanyu Mechanical is famous hammer crusher manufacturer or hammer mill crusher supplier in China, and the hammer crusher and hammer crushing machine produced by Lanyu is with advanced designing technology, compact structure, shock resistance, strong crushing ability and other advantages. Welcome customers from all over the world to visit for cooperation.

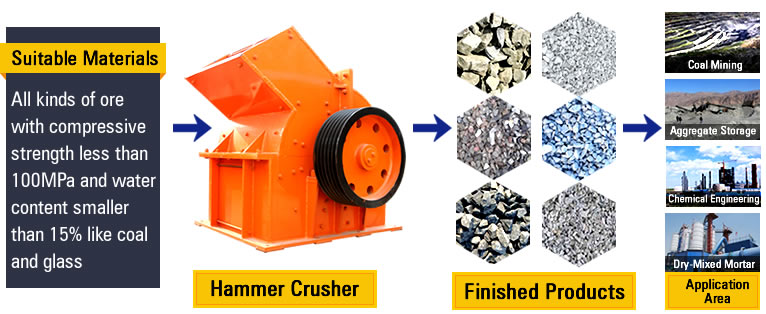

Hammer crusher is also called hammer mill crusher. Hammer crusher is a single-stage crushing machine that can directly crush the materials whose maximum granularity is 600-180 mm to 25 mm or below. It is suitable for the medium and fine crushing of medium hard materials in cement, chemistry, power and metallurgy.

Hammer crusher is widely used in the mining, cement, coal, metallurgy, building material, highway and burning industries for crushing materials with the medium hardness and brittle property. The grate gap of hammer crusher can be adjusted according to different particle size requirements of users.

Features of hammer crusher

1. The hammer head adopts the new casting process, which has the advantages of wear resistance and impact resistance.

2. Large feed particle size, high yield, good grain shape.

3. The granularity can be adjusted according to customer requirements.

4. The body has sealing structure, which solves the ash leakage and dust pollution problems of crushing workshop.

5. Beautiful appearance, compact structure, less wearing parts, convenient maintenance, good wear resistance.

Working principle of hammer crusher

When the hammer crusher or hammer crushing machine works, the motor drives the rotor to spin at high speed, materials are fed into the crushing cavity evenly, and then be impacted, cut and tore by high speed spinning hammerhead till they are completely crushed. Meanwhile, the gravity action of materials forces them to crash the baffle and grate bars on the frame. Materials with particle size smaller than the screen size will pass the sieve plate while those with bigger particle size are stopped on the plate and will continue to be impacted and grounded by the hammer until they are crushed to the required particle size, finally, crushed materials will be discharged from the hammer crusher through the sieve plate.

Structure of Hammer Crusher

The hammer crusher mainly consists of the box, disk, axis, hammer, grates, adjusting frame and coupling. The housing of the hammer crusher is a box made of steel plate, which can be divided into two parts along the center of the axis. The two parts are connected by the bolts. To avoid abrasion and transformation of the inner wall of the box under the impact of the materials, there are protecting scale boards in the housing of the hammer crusher. The types of disk are triangle and circle, with the former easy to be abraded than the latter. There are 6 mandrels on the disk, through which the hammers are installed staggered on the disk.

Technical Data of hammer crusher

|

Model Specification |

Feeding Size (mm) |

Discharging Size (mm) |

Capacity (m³/h) |

Motor power (kw) |

Total weight(t) |

Dimensions (L*W*H)(mm) |

| PCØ400*300 | <=200 | <=25 | 5-10 | 11 | 0.8 | 900*670*860 |

| PCØ600*400 | <=250 | <=30 | 10-22 | 22 | 2.26 | 1200*1050*1200 |

| PCØ800*600 | <=250 | <=35 | 18-40 | 55 | 4.8 | 1310*1180*1310 |

| PCØ1000*800 | <=350 | <=35 | 25-50 | 75 | 5.9 | 1600*1390*1575 |

| PCØ1000*1000 | <=350 | <=35 | 30-55 | 90 | 8 | 1800*1590*1775 |

| PCØ1200*1200 | <=350 | <=35 | 50-80 | 132-160 | 19.2 | 2060*1600*1890 |

| PCØ1400*1400 | <=350 | <=35 | 50-100 | 280 | 32 | 2365*1870*2220 |

| PCØ1600*1600 | <=350 | <=35 | 100-150 | 480 | 37.5 | 3050*2850*2800 |

Inquiry* Describe Your Buying Requirements in Detail,We will reply you in 24 hours!