The china impact crusher is a new type of highly efficient crushing machine. Impact crusher or impact breaker features small size, simple structure, high crushing ratio, low energy consumption, high yield, evenly product particles and selecting crushing function, which makes it a promising machine in the future.

The china impact crusher is a new type of highly efficient crushing machine, with the characteristics of small size, simple structure, high crushing ratio (reaching 40), low energy consumption, strong production ability and well distribution of particles, and a more significant function of crushing selectively makes it a very promising crushing machine. It has been applied in some ore dressing plants owing to the appearance of highly-abrasive materials.

As high-efficiency crushing machine, the impact breaker can handle materials with side length between 100 to 500 mm. Impact crusher or impact breaker features small size, simple structure, high crushing ratio, low energy consumption, high yield, evenly product particles and selecting crushing function, which makes it a promising machine in the future. In China, Zhengzhou Lanyu Mechanical Equipment Co., Ltd. possesses good fame at home and abroad, and the impact crusher for sale enjoys high popularity among the customers. We believe that Lanyu Machinery will be your nice choice.

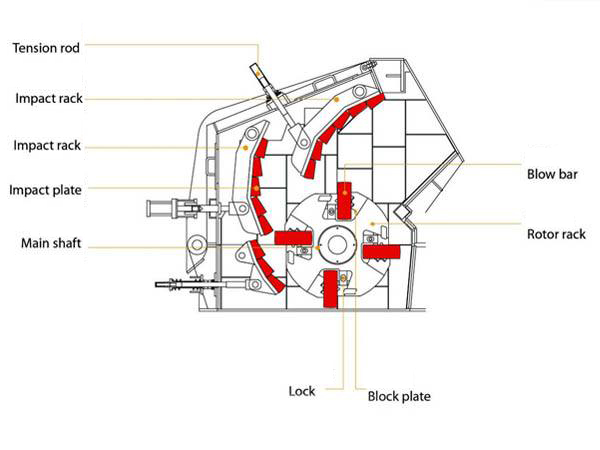

Structure of Impact Crusher

The impact crusher is mainly made up of rotor rack, impact rack, ratchet wheel cover-open device, rotating parts as well as other components.

There are two parallel rotors in the mobile impact crusher, with some altitude differences. The position of the first rotor is relatively high, with an angle of 12¡ã from the ligature of the first and the second rotor. The first rotor is a heavy type, used for coarse crushing; the second rotor rotates fast, which can meet the need of the final products. The rotors are both fixed with bolts. The 12 blow bars distributed to 6 rows are made of high manganese steel. The rotors are fixed on the main shaft, separately connected with the coupling of two engines. All impact boards are made of high manganese steel.

Working Principle of Impact Crusher

The materials fall to the high-speed rotating turn plate. With the effect of high-speed centrifugal force, these materials will impact with other particles distributed around the turn plate. After inter-impacting, these materials will impact, abrade and crush between the turn plate and the enclosure continuously, and then discharged from the bottom. The impacting, abrading and crushing process will form a closed cycle, with the screening equipment controlling the particle sizes for need.

Technical Data of Impact Crusher

| Model |

Specification (mm) |

Feed opening (mm) |

The Maximum Feeding Size (mm) |

Capacity (t/h) |

Power (kw) |

Total weight (t) |

Overall dimension (L*W*H) (mm) |

| PF-1007 | Ø1000*700 | 400*730 | 300 | 30-70 | 37-45 | 12 | 2330*1660*2300 |

| PF-1010 | Ø1000*1050 | 400*1080 | 350 | 50-90 | 45-55 | 15 | 2370*1700*2390 |

| PF-1210 | Ø1250*1050 | 400*1080 | 350 | 70-130 | 110 | 17.7 | 2680*2160*2800 |

| PF-1214 | Ø1250*1400 | 400*1430 | 350 | 100-180 | 132 | 22.4 | 2650*2460*2800 |

| PF-1315 | Ø1320*1500 | 860*1520 | 500 | 130-250 | 220 | 27 | 3180*2720*2620 |

| PF-1520 | Ø1500*2000 | 830*2040 | 700 | 300-550 | 315-400 | 50.6 | 3959*3564*3330 |

| PF-1820 | Ø1800*2000 | 1260*2040 | 800 | 600-800 | 630-710 | 83.21 | 4400*3866*4009 |

Inquiry* Describe Your Buying Requirements in Detail,We will reply you in 24 hours!