Zhengzhou Lanyu Mechanical Disk Granulator is transformed on the basis of advanced technologies of similar equipment at home and abroad. Disk grain making machine is actually feeding equipment based on volumetric measurement.

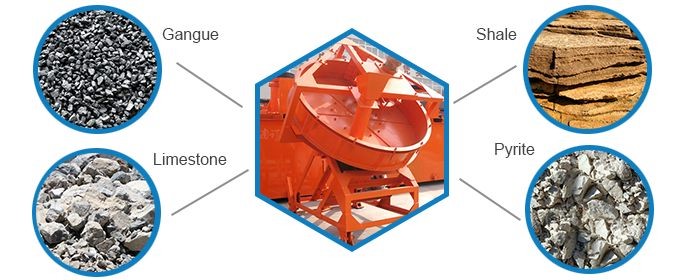

Zhengzhou Lanyu Mechanical Disk Granulator is transformed on the basis of advanced technologies of similar equipment at home and abroad. Disk grain making machine is actually feeding equipment based on volumetric measurement, and it can feed materials uniformly and continuously, and able to take higher warehouse pressure. As a feeding device for fine material, it's suitable for the transportation of a variety of powdery and small non-viscous materials, such as coal, cement, clinker, limestone, clay, shale, coal gangue, powder, granular or small-block materials. Lanyu Mechanical disk grain making machine can be widely used in gold, coal mining and chemical plant, infrastructure and mechanized foundry for feeding materials uniformly and continuously.

The Application and Usage of Disk Granulator

It is widely used in gold concentrator, coal mine, chemical plant, construction and foundry for quantitative and even feeding. Advantages of this machine are: simple structure, easy-to-adjust and excellent in performance.This machine is suitable for conveying of materials with granularity less than 50mm, while it is not suitable for cohesive materials, easy-to-flow or hard-to-flow materials.

Features of Disk Granulator

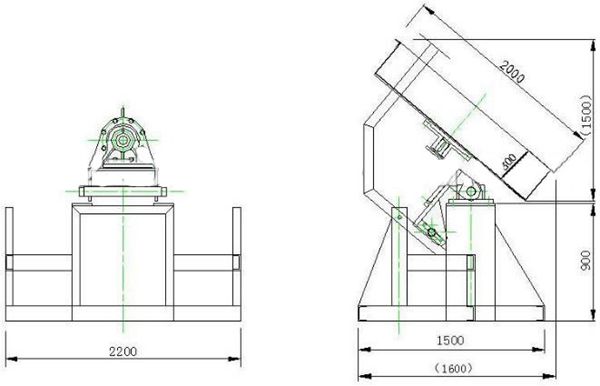

1. Disk granulator¡¯s structure is new and suitable. Its weight is light. Its height is low. Its process layout is flexible. And it is suitable to reformation of old factory.

2. The tilt of market is adjustable. Disc granulator uses angle of gasket, which makes it convenient to adjust.

3. Disk granulator adopts unpowered composite scraper, which can help it decrease power consumption.

Structure and Introduction of Disk Granulator

The granulation rate is more than 93%. There are three discharging ports in disc granulator, which is convenient for discontinuous production, reduces laboring strength, and improves production efficiency. Reduction gears and motor rotate by flexible belts, which can reduce impact, start steadily and prolong serving life. Pan bottom of it uses steel plate which is sturdy and durable. Thicker, heavier and solid base design need not use bolts to fix.

Technical Data of Disk Granulator

|

Specification

(m) |

Rotation speed

(r/min) |

Production capacity

(t/h) |

Motor

(kw) |

Adjustment range of obliquity

|

Dimensions

(m) |

Total weight

(kg) |

|

Ø2.2

|

14.25

|

4-8

|

7.5

|

35-55

|

2.8*2.75*2.58

|

2850

|

|

Ø2.5

|

11.81

|

5-10

|

7.5

|

35-55

|

3.2*2.3*3

|

3250

|

|

Ø2.8

|

11.21

|

12-16

|

7.5

|

35-55

|

3.4*2.6*3.1

|

3710

|

|

Ø3.0

|

11.3

|

15-18

|

11

|

35-55

|

3.7*2.7*3.3

|

4350

|

|

Ø3.2

|

9.6

|

15-20

|

11

|

35-55

|

3.9*2.7*3.4

|

5110

|

|

Ø3.6

|

9.1

|

18-24

|

15

|

35-55

|

4.3*3.1*4.0

|

6510

|

Inquiry* Describe Your Buying Requirements in Detail,We will reply you in 24 hours!