Raymond Mill, also known as raymond grinder, raymond grinding mill and raymond pulverizer, is commonly used grinding equipment. It is suitable for processing various non inflammable minerals with 7 grade Mohs hardness and less than 6% humidity, such as gypsum, talc, oxide iron red, iron ore, etc.

Raymond Mill, also known as raymond grinder, raymond grinding mill and raymond pulverizer, is commonly used grinding equipment, mainly used for grinding barite, calcite, feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate ore, gypsum, glass, insulation materials and other materials with Mohs hardness not more than 7 degree and humidity below 6% in mineral, chemical, construction and other industries. Final size of finished products can be adjusted within 60-325 meshes.

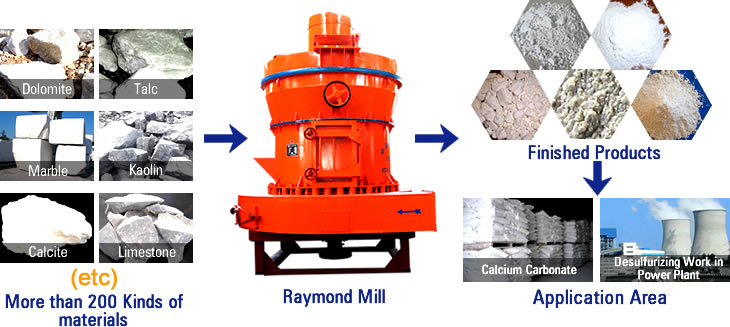

Applied Materials of Raymond Mill

It is suitable for processing various non inflammable minerals with 7 grade Mohs hardness and less than 6% humidity, such as gypsum, talc, calcite, limestone, marble, feldspar, dolomite, barite, granite, kaolin clay, stone, bauxite, oxide iron red, iron ore, etc. The fineness of its finished product is 613-44 microns (0.613 mm -0.044 mm).

Raymond Mill Working Principle

When the raymond mill works, the materials that need to be crushed are fed into the machine through the feeding hopper. The grinding roll of raymond grinder, raymond grinding mill or raymond pulverizer hangs on the main engine will rotate around the vertical axis and rotates around itself. Due to the centrifugal force produced in the rotating process, the grinding roll will swings outward and tightly press onto the grinding ring to make the relieving tool scoop up the materials and send them to the space between the grinding roll and the grinding ring, and the materials will be crushed due to the rolling and grinding of the grinding roll.

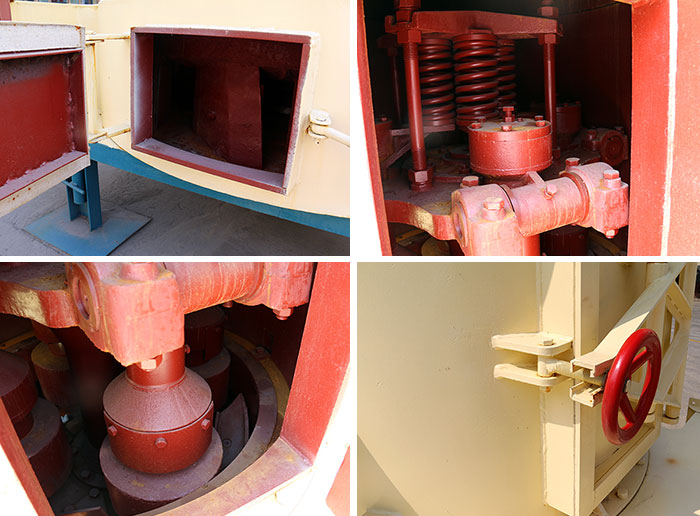

The Interior Structure of Raymond Mill

1. Compared with other milling plants, its passing ratio achieves 99%, which is what other mills cannot reach.

2. Driving system of main frame adopts airtight gearing and pulley, drives smoothly and operates reliably.

3. Main parts of the whole plant are made from cast and steel of high quality. The techniques are so subtly that they ensure the durability of whole plant.

4. The electric control system is centralized controlled, so the automaticity is high, no people are needed in the operating room.

The Characteristics of Raymond Mill

1. Systematic, high through screening rate.

The three-dimensional structure is systematic with small footprint. From the rough processing, delivery to the grinding and the final packaging, it can become an independent production system. The finished powder has uniform fineness, and as high as 99% through screening rate.

2. Smooth transmission, high abrasion resistance.

The transmission device adopts sealed gear box and pulley to achieve smooth transmission and reliable operation. The core components are made of wear-resistant materials with high performance and high abrasion resistance to save the production cost.

3. Easy to control, convenient maintenance.

The electrical system adopts centralized control and the workshop basically can realize non-person work. It adopts the electromagnetic vibration feeder to realize continuous and uniform feeding, which has easy adjustment and convenient maintenance.

Zhengzhou Lanyu Mechanical is one professional Raymond mill manufacturer, if you want to know more information about our Raymond mill price, please leave us a message below or send us an email to Lanyu@Lanyuroup.com, we will contact you as soon as possible!

Technical Parameter of Raymond Mill

| Model | 4525 | 4119 |

| Feeding Size(mm) | <=30 | <=25 |

| Output Size(mm) | 0.044-0.173 | 0.044-0.173 |

| Shift Output of Different Material Fineness(t) | 16-176 | 8-78 |

| Rotation Speed of Central Shaft(r/min) | 82 | 105 |

| Ring Diameter(mm) | 1770 | 1400 |

| Roller Diameter(mm) | 450 | 410 |

| Roller Height(mm) | 250 | 190 |

| Main Motor | y315m-4-132 | y280s-4-75 |

| Fan Motor | y315m-4-132 | y250m-4-75 |

| Analyzer Motor | YCT250-4A-18.5 | YCT200-4B-7.5 |

Inquiry* Describe Your Buying Requirements in Detail,We will reply you in 24 hours!