High-frequency Screen consists of vibration exciter, ore pulp distributor, screen frame, machine frame, suspension springs and sieve, etc. This series screen is always used in processing minerals such as ferrous metals including hematite magnet and nonferrous metals including lead, zinc, gold and silver, etc.

High-frequency Screen consists of vibration exciter, ore pulp distributor, screen frame, machine frame, suspension springs and sieve, etc. This series screen is always used in processing minerals such as ferrous metals including hematite magnet and nonferrous metals including lead, zinc, gold and silver, etc. This machine works in a re-circulating network with ball mill, which can upgrade the fineness of ferrous and nonferrous metals. Its efficiency is twice that of spiral classifier. It adopts the high frequency and low amplitude vibration for the processing of powder in coal, metallurgy, electricity, construction and chemical industry.

The Advantages and Benefits of High Frequency Screen

High efficiency, small amplitude and high frequency of screening; it differs from the conventional screens with breaking of the surface tension of pulp and high speed vibration on sieve cover and accelerates the separating of large-density useful mines and increases the contacting probability of the materials smaller than output granularity and the sieve pore. Therefore, it results into good condition and makes the materials smaller than the output granularity, especially the big-density materials and pulp get through the sieve pore together.

Features of High Frequency Screen

1. Using laminated mesh increases monolayer aperture, which not only increases the useful life of the screen, but also can prevent jamming and wearing.

2. The rubber spring of high frequency screen supports the screen frame, which can reduce noise and set vibrating.

3. It is low amplitude, which makes for the classification of fine and heavy materials.

4. Strong production capacity, low energy consumption.

The Working Principle of High Frequency Screen

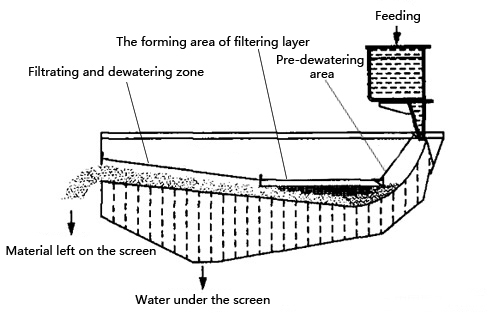

High frequency vibrating mesh screen consists of base, frame, and rubber damping spring, low frequency electromagnetic vibrator, screen box, mesh screen, high frequency electromagnetic vibrator, support, angle adjustment bar and electronic control box. When the machine operates, the low frequency electromagnetic vibrator vibrates the feeder and outputs part of the mesh screen directly to move the whole screen. At the same time, the high frequency electromagnetic vibrator shakes the middle of mesh screen through the rubber cushion. The mesh screen is composed of three stainless steel screen layers; the lowest screen layer is high strength primary screen which is connected with the shake motor; the other two layers are workable screen in mine processing.

Technical Parameter of High Frequency Screen

|

Specification Model |

Screen area(m³) |

Thickness of input material(%) |

Processing capacity(t/h) |

Power (kw) |

| GPS-2*2 | 3.0 | 30-40 | 10-15 | 0.75 |

| GPS-2*3 | 4.5 | 30-40 | 15-25 | 1.5 |

| GPS-2*4 | 6.5 | 30-40 | 24-36 | 2.25 |

| GPS-2*5 | 8.7 | 30-40 | 32-48 | 3 |

Inquiry* Describe Your Buying Requirements in Detail,We will reply you in 24 hours!