Magnetic Separator is also called magnetic drum separator. Magnetic separatorcan be divided into dry magnetic separator and wet magnetic separator. Magnetic separator has wide applications in the production of industrial plant, and magnetic separator is also in continuous improvement with development of science and technology.

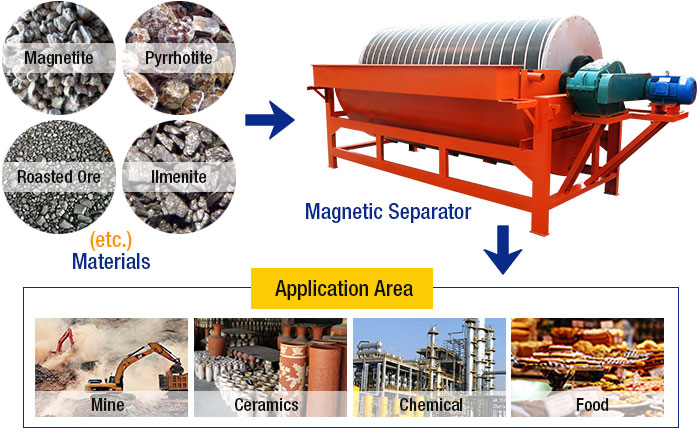

Magnetic Separator is also called magnetic drum separator. It is a kind of indispensable ore dressing equipment in magnetic separation production line, which is suitable for the removal of iron in the reused powder materials. Magnetic separator is mainly composed of four parts: cylinder, magnetic system, tank body and transmission part, which is widely used in resource recovery industry, wood industry, mining industry, ceramics industry, chemical industry, food and other workshops. Magnetic separator is suitable for the wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite and other materials with below 3mm particle size, which is also used for iron removal of coal, non-metallic minerals, building materials and other materials. It is one of the most widely used high versatility equipment in aircraft industry.

Classification of Magnetic Separator

Magnetic separatorcan be divided into dry magnetic separator and wet magnetic separator. Magnetic separator has wide applications in the production of industrial plant, and magnetic separator is also in continuous improvement with development of science and technology. The improvement of magnetic separating technology has a direct relationship with the industrial plant, so the structure transformation of the magnetic separator equipment becomes necessary.

Application of Magnetic Separator

The magnetic drum separator or the wet magnetic separator machine is used to remove the iron powder form the particle and powder materials and to recycle resources in the industries of wood, mine, ceramics, chemical and food. Magnetic drum separator can not only complete the wet magnetic separation of materials with the particle size smaller than 3mm such as magnetite, pyrrhotite, roasted ore and ilmenite etc, but also remove iron from the coal, non-metal and construction materials. So magnetic drum separator is the wet magnetic separator machine with the highest universality and the widest application range.

China magnetic separator manufacturer

Zhengzhou Lanyu Mechanical is a professional wet magnetic separator manufacturer which makes the magnetic separator, strong magnetic separator, wet and dry separating equipment, iron ore and permanent magnet cylinder separator. Lanyu Mechanical has many years¡¯ experience of making magnetic separators and we have strong technical advantages and production strength. The company with the strong strength and advanced technology is a well known manufacturer with customers¡¯ trust and support.

Technical Data of Magnetic Separator

| Model |

Shell diameter (mm) |

Shell lenght (mm) |

Shell rotation speed(r/min) |

Feeding size (mm) |

Processing capacoty (t/h) |

Power (kw) |

| CTB6012 | 600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

| CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

| CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

| CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

| CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

| CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

| CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

| CTB1021 | 1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

| CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

| CTB1218 | 1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

| CTB1224 | 1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

| CTB1230 | 1200 | 3000 | <18 | 3-0 | 100-180 | 7.5 |

| CTB1530 | 1500 | 3000 | <14 | 3-0 | 170-280 | 11 |

Inquiry* Describe Your Buying Requirements in Detail,We will reply you in 24 hours!