Trommel Screen is a dedicated screening equipment which is used in power plant, coking plant, building materials, metallurgy, chemical industry, mining and other industries. It solves the problem of screen mesh plug when classify wet materials by circular vibrating screen and linear screen.

Trommel Screen is a dedicated screening equipment which is used in power plant, coking plant, building materials, metallurgy, chemical industry, mining and other industries. It solves the problem of screen mesh plug when classify wet materials by circular vibrating screen and linear screen.

The Advantages and Benefits of Trommel Screen

1. The sieve pore is not easy to be blocked;

2. Steady performance and low noisy;

3. Simple structure and convenient maintenance.

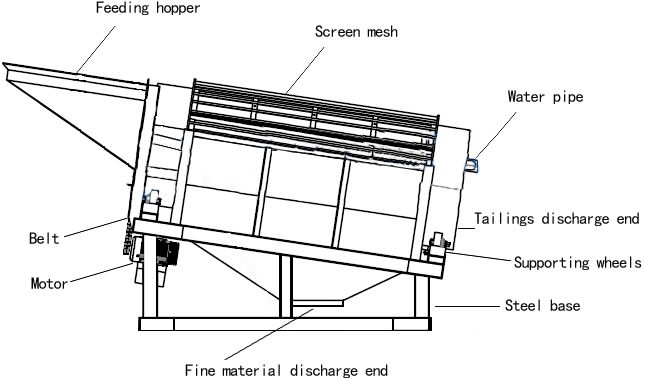

The Inner Structure of Trommel Screen

Drum screen is divided into two parts: screen drum and transmission parts. The screen drum for cylindrical tank, mainly consists of sieve plate, stock guide, frames and other components. The sieve plate is made by 65Mn, and the mesh size is normally determined according to user requirements. Stock guide is removable. When the material is no less than 60mm, remove stock guide, when material is with size of 15mm ¡Ü 60mm, keep the stock guide. Transmission mainly uses the friction drive.

Working principle of Trommel Screen

The roller is installed tipsily on the rack. The motor contact with the roller by the couple though reduction gears. The roller rotates around its axis drove by the motor. When the materials enter into roller, the materials on the surface of screen will overturn and roll as the screen. Because the whole slant set is running and turning. The qualified materials will be discharged out from the bottom of the roller. And the unqualified materials will run out from the opposite side. Materials overturn and run ceaselessly. So if there are materials locked in the hole of screen, they will be ejected, which can prevent the screen hole from blocking.

Technical Parameter of Trommel Screen

| Type | Model and Specifications | Working Area(m³) | Screen Layer | Max. Feeding Size(mm) | Processing Capacity(t/h) | Screen Size(mm) | Vibration Times | Power(kw) |

| Self-fixed Centre Vibrating Screen | 400*800 | 0.29 | 1 | 50 | 12 | 1-25 | 1500 | 1.1 |

| 400*800 | 0.29 | 2 | 50 | 12 | 1-15 | 1500 | 0.5 | |

| 800*1600 | 1.2 | 1 | 100 | 20-25 | 3-40 | 1430 | 2.2 | |

| 900*1800 | 1.52 | 1 | 60 | 20-25 | 1-25 | 1000 | 2.2 | |

| 900*1800 | 1.52 | 2 | 60 | 20-25 | 1-25 | 1000 | 2.2 | |

| 1250*2500 | 3.15 | 1 | 100 | 150 | 6-40 | 850 | 5.5 | |

| 1250*2500 | 3.15 | 2 | 150 | 150 | 6-40 | 1200 | 5.5 |

Inquiry* Describe Your Buying Requirements in Detail,We will reply you in 24 hours!